2021 ABC Raceway “Six Cylinder” Rules

Any American made car with a minimum 108” wheelbase. No V-6 engines allowed.

All cars have a minimum weight requirement based upon their engine type, with

driver, after each of their respective races. See below for weight requirements:

GM: 2,600 lbs.

Ford: 2,650 lbs.

Mopar: 2,650 lbs.

AMC: 2,650 lbs.

• There will be no team drivers allowed. All points will be awarded to

individual drivers.

1. ENGINE

Any American made car with a minimum 108” wheelbase. No V-6 engines allowed.

All cars have a minimum weight requirement based upon their engine type, with driver, after each of their respective races. See below for weight requirements:

GM: 2,600 lbs.

Ford: 2,650 lbs.

Mopar: 2,650 lbs.

AMC: 2,650 lbs.

• There will be no team drivers allowed. All points will be awarded to individual drivers.

A. GM, Ford, Mopar, and AMC. 1-BBL version carburetor allowed only. No overhead cams allowed. Maximum cubic inch limits are as follows: GM: 250 C.I.; Ford: 240 C.I.;

Mopar: 225 C.I.; AMC: 258 C.I.

B. Only engine parts allowed will be of the standard 1BBL version with any stock 1BBL intake manifold. Crankshaft and connecting rods must be O.E.M to block with no lightening, grinding, knife edging or polishing of any type. No aftermarket rods or crankshaft. Aftermarket rod bolts allowed. Straight cut cam gears, 3-keyways allowed. Any battery allowed. 17.5V maximum output step-up allowed, as well as step-downs. Mini starters allowed, aluminum pulley allowed. Balancing of motor legal. No marine engine parts allowed. No reverse spin rotation motors.

C. Maximum overbore of .060 allowed.

D. Heads must match cubic inch displacement of block.

E. Any hydraulic cam allowed. Hydraulic lifters only Mopars are allowed to use a solid cam if it is stock for year and make of motor.

a. Any stock single wire valve springs allowed, up to 1.270 diameter. Valve spring shims allowed. Steel retainers and keepers allowed. Lifters must be stock diameter for make of engine and no mushroom lifters allowed. Lifters must be steel or iron and must be free to rotate.

b. Rocker jam nuts and screw in studs allowed. Studs may be be pinned. No roller type or roller-tip rockers allowed. O.E.M. type stamped steel rockers only, slots can be elongated. No stud girdles allowed. Lifter bores may not be bushed.

C. Any stock size six cylinder valves per manufacturer. No titanium valves allowed.

F. No grinding, polishing or porting of any kind on the head or intake. Valve seats may be ground no more than 1⁄4” below top of seat. Head may be milled. Angle milling allowed. Push rod holes may be enlarged. Shortened push rods will be allowed.

a. No excessive bead blasting of intake. Required dimensions to be determined by Board; will become effective and enforceable at date of Board’s approval.

G. Stock type distributors only. Stock type module, stock type coil. Location must match distributor being used. Any mechanical or vacuum advance allowed. No multiple spark boxes allowed. No magnetos allowed. No crank trigger ignition. Welding mechanical advance open is allowed.

H. No electronic traction controls.

I. Exhaust manifold must be the 2” diameter version with a 1/8” tolerance. No grinding, polishing or machining of any kind.

J. Maximum piston deck clearance is “0”. If a straight edge catches piston at T.D.C. it will be considered illegal.

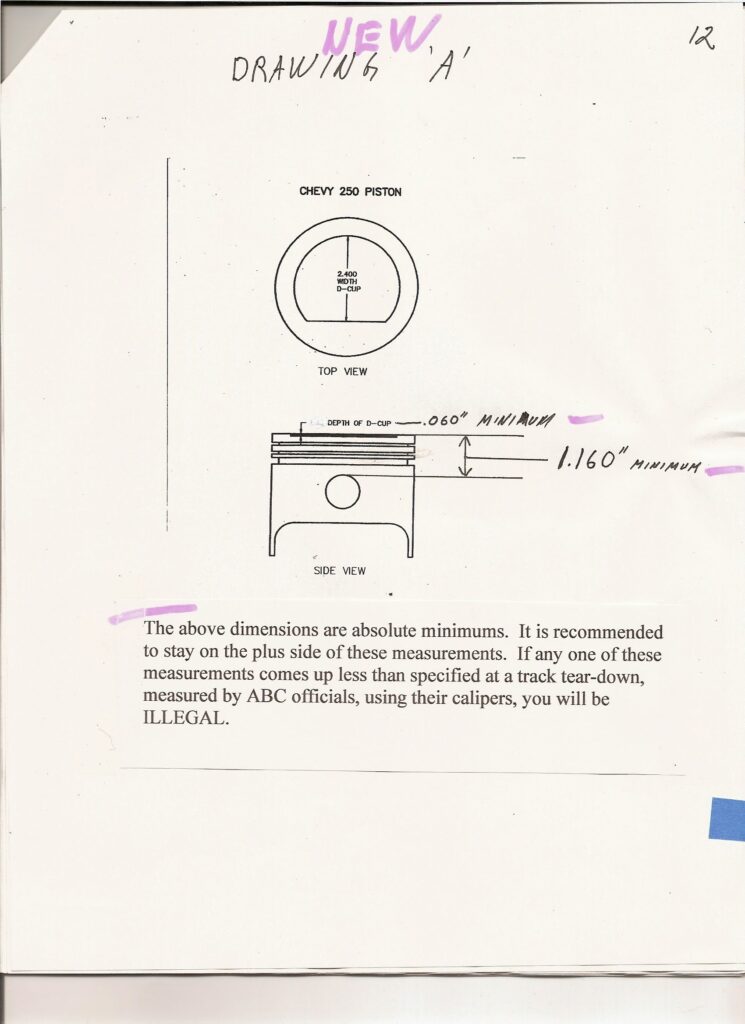

K. Any cast or hypereutectic cast piston allowed. The depth of the “D” cup must be a minimum of .060”, with the size of the “D” to be 2.400” minimum from the flat side

to the outside edge. Any rings allowed. See “Drawing A” for piston dimensions. Cutting of piston top to match these dimensions is allowed. These are minimum dimensions, do not be less than these.

L. Stock Stroke +.005 inch maximum.

M. Any fan, water pump, and oil pan allowed. No electric fan or electric water pump allowed. Any steel OEM balancer or any steel SFI approved balancer allowed. No after market power steering pump allowed. Serpentine belt not allowed.

N. Engines must be tied down with a chain or solid motor mount. Minimum of 90” from center of rear end housing to back of block with a one-inch (1”) tolerance.

O. Stock carburetor for make and model of engine for Ford, Chrysler and AMC.

a. GM must use Rochester 1BBL carburetor.

I. Devices below the carburetor designed to increase the flow of air are not

permitted. Maximum 1⁄4” gasket allowed.

II. All air entering the engine will be required to enter through the top of the carburetor.

III. 5” maximum straight bore spacer between top of carburetor and bottom of air cleaner.

P. Any radiator is allowed without altering the outside appearance of body. (Such as cutting the hood).

Q. Balancer cover allowed.

2. TRANSMISSIONS

A. Stock transmissions overdrive, 3-speed or 4-speed allowed. No automatic transmissions allowed. All transmissions must have all working gears. No lightening of rotating parts. GM-to-GM, Ford-to-Ford, etc.

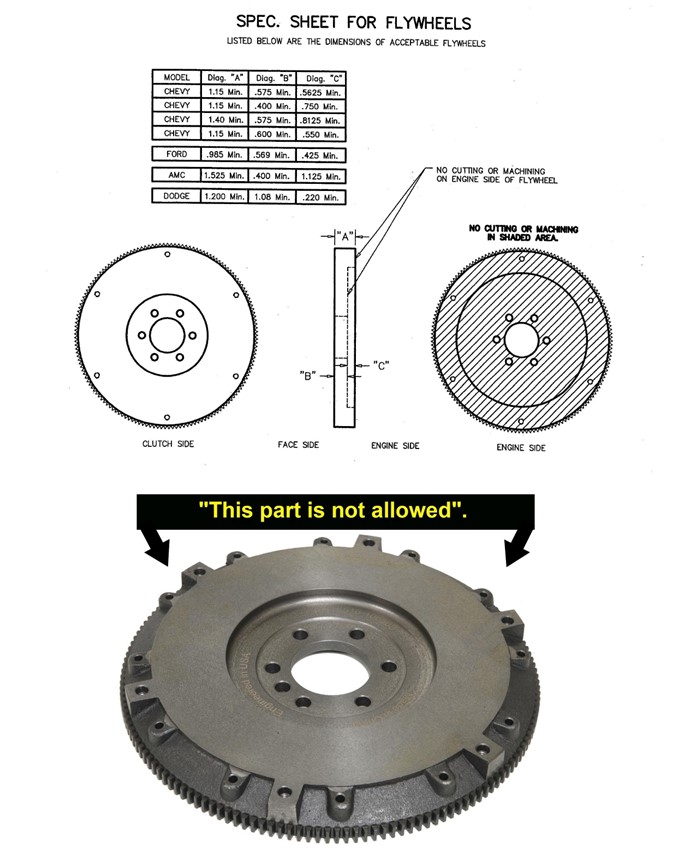

B. No cutting or drilling on back of flywheel. (See attached spec. sheet)

a. Flywheels to be all steel, showing part number. Stock pressure plate only. Stock type or solid hub clutch disc allowed. Solid disc recommended for safety reasons. Solid hub disc must have full circle lining.

C. No aluminum, chopped or Corvette-style flywheels. No aluminum pressure plates allowed. No lightening of any clutch parts.

D. Steel bell housing mandatory or 1/8” steel 360 degree shell of minimum 4” width or SFI explosion blanket.

E. Manual linkages or hydraulic clutch cylinder allowed.

3. TIRES AND WHEELS

A. Hoosier Dirt Stocker 500 or Hoosier Wissota 35. There will be no defacing or altering of manufacturer’s identification markings on the tire. You may not remove any letters, words or numbers that would identify the tire.

B. Steel wheels only, up to 8” allowed.

C. Bead lock optional on right rear only. No other bead locks or screws allowed.

D. Oversized lug nuts mandatory.

E. Up to 1” wheel spacers or adapters allowed.

F. Grooving and sipping of tires to be allowed.

G. No chemical treating of tires.

H. Mud plugs allowed.

4. FUEL

A. No electric, belt driven or piston type fuel pumps allowed. Must be stock diaphragm type fuel pump.

B. Gas only. Racing gas allowed. Ethanol enriched gasoline may be used. No alcohol, no nitrous, no nitrous devices allowed. No methane or propolene oxide allowed.

C. Fuel overflow hoses must be mounted below cell.

D. Fuel lines in driver’s compartment must be enclosed in metal tubing. (It is recommended that fuel lines not be in driver’s compartment).

5. CAR BODIES

A. Any after market body and plastic nose piece allowed.

B. Must have complete body. Must be centered on front stub. Metal, aluminum or fiberglass hoods and roofs are allowed. (Look at Wissota Super Stock Rules for guidelines).

C. Inner panels, dash and trunk may be removed. Floorboard must be of steel and a minimum of 20-gauge thickness from the firewall to the rear of the driver’s seat on the driver’s side. If passenger floor is removed, driver’s compartment must be tinned in (completely enclosed).

D. Area around driver’s compartment must be enclosed (cockpit style).

E. Must have full roofs. Maximum of a 2” slope on roof line.

F. Car must have neat appearing paint job with an 18” minimum height number in contrasting color on both doors and roof. Must have numbers on front and rear of car.

G. Optional back panel from top deck tin to bumper, a minimum of nine inches, extending from left to right side.

H. Spoilers must be 4 inches in height. Spoiler supports can be 5 inches in height.

6. SUSPENSION

A. Front and rear sub frames must be tied together with a 108” wheelbase (one-inch tolerance allowed).

B. Stock steering rods and A-frames for front stub. A-frames may be reinforced. Rag joints must be replaced with a steering U-Joint. Stock steering box only. No steering quickeners allowed.

C. Any rear shackle up to 4-1⁄2 inches from hole center to hole center. Equal length side to side.

D. No rack and pinion steering.

E. Aluminum lower blocks and adjustable lowering blocks are allowed.

G. Front suspension: all components must be steel unaltered O.E.M. in O.E.M. location and replaceable by O.E.M. parts. Exceptions are: tube type upper A-frames are allowed and upper A-frame mounts may be moved in or out to adjust for camber. After market upper ball joints are allowed. Lower A-frames must be stock but may be cut for shock. Lower A-

frame mounts must not be altered and must be in stock location. Spindles and bottom control arms must be the same side-to-side. Bottom A-frame bushings must be in stock location. Bottom A-frame bushings must have bolt hole in the center of bushing, not an offset bolt hole. Lower ball joint may be aftermarket, but must be steel and must remain in stock location plus or minus .25”. Any stock anti-sway bar may be used. Steel heim joints and steel swedge tubes are allowed on outer tie rods.

H. Stock passenger car spindles and hubs only. No fabricated spindles or hubs. Intermarriage is permitted within manufacturers (GM for GM, Ford for Lincoln or Mercury) but rotors, calipers and spindles must match. On stock-finned rotors, rotors must remain stock diameter with stock calipers and stock caliper mounts. No lightening or grinding.

I. All coil springs whether front or rear suspension must be a minimum outside diameter of 4-1/2 inches. After market springs allowed. No fiberglass leaf springs allowed. Multiple holes allowed on front leaf spring mount. Sliders allowed in rear leaf spring mounts only.

J. Rear suspension: multiple holes will be allowed on rear suspension mounts. Lower and upper control arm mounts must be mounted solid to the tube. No birdcages or adjustable mounts allowed. Springs, fixed or pivoting, must be mounted on the lower control arm or the axle tube itself, and must be the same on both sides. Springs may not be mounted behind axle tube. Weight jacks are allowed. No coil-overs or coil-over eliminators of any sort allowed on front or rear of car. Steel rear suspension arms only, any bushing for upper or lower control arms may be a maximum outside diameter of 2-1/2 inches and must be round. Bushings may be made of any material. One (1) shock per wheel only with a total of 4 shocks per car. Front side of shocks can be covered. No remote or external canister shocks allowed. Racing shocks allowed. Non-adjustable shocks, steel only. No air shocks, air bags, load levelers or overloads allowed. No milling, drilling or lightening up on any frame or suspension parts allowed. Rear shocks must be mounted behind the rearend. No anti-sway bar may be used on the rear. No lift bars, snubber bars, J-bars or any other traction devices allowed. Panhard bar allowed on 3-link suspension only.

K. 3-link suspension: (refer to diagram) third link runs parallel with the frame, perpendicular to the axle. Panhard bar mount and upper control arm mount must be a minimum of 9 inches from the center of the housing on the right hand axle tube. Panhard bars must be mounted behind rear end.

L. After market pedals with balance bar allowed.

M. Steering: Steering box must remain in stock location and be mounted in original holes. In cockpit steering may be modified to suit driver’s taste. But must be kept on the left side of the cockpit. No center steering. Solid steel steering joint mandatory in steering shaft. Boxing in of steering column not allowed. No rack and pinion steering.

N. Balance bar brake systems with bias handle removed is allowed.

O. Shock claim allowed. Drivers finishing sixth or worse, and on the lead lap, may claim shocks of one car that finished in first through fifth position. Each car is allowed two claims per year, and can claim up to four shocks per each claim event. Cost of claim is

$50 per shock.

7. REAR ENDS

A. GN as well as Grand National type rear ends allowed.

B. May run half-ton Ford rear end. Locked rear ends or posi-traction allowed. No aftermarket traction devices allowed. Mini and full steel spools allowed. No aluminum carriers. No limited slip type rear ends allowed, (Gold Track, Detroit, Lockers, etc.). Aftermarket axels allowed. No gun-drilled axles, no lightening axles.

C. Any gear ratio allowed.

D. Any passenger car or truck stock appearance rear end may be used.

E. Quick change rear ends are not allowed.

F. No lightweight metal rear ends allowed including aluminum, titanium, or magnesium except aluminum leaf spring blocks, shackles, trailing arms with steel heim joints, and aluminum drive plates and dust caps may be used but only on Grand National rear ends. Steel rear suspension/trailing arms

8. BRAKES

A. Drum brakes or disk brakes on rear.

B. Aftermarket or manual pedal system for clutch, brake, and throttle allowed. Aftermarket brake reservoirs allowed.

C. No brake shut-off valves allowed.

D. Must have four working brakes.

E. Brake residual valve OK if located within six inches (6”) of master cylinder and BEFORE the “T” on EACH line.

F. Must have brakes on each wheel, this includes 4 calipers and 4 rotors (no aluminum calipers). Must be able to lock up all 4 wheels. Rear brakes may be drum or disc type. No floating brake caliper mounts allowed. No carbon fiber brakes (steel components only). Sliders allowed in rear leaf spring mounts only.

9. ROLL CAGES

A. All cars must have a six-point (6 point) roll cage securely mounted to frames.

B. Minimum of three (3) bars along drivers door and must follow the contour of the door.

Must have a minimum of two (2) bars along side of passenger door.

C. Bars to be 1 1⁄2” O.D. with a .095” wall thickness or 1 3⁄4” O.D. and 3/32” wall

thickness. No galvanized or black pipe allowed.

D. All cars must have a 1⁄2” diameter bar in the middle of the windshield opening. Must

have a screen or a minimum of four (4) – 1⁄2” bars in front of driver.

E. All welds must be 360 degrees and pass a safety inspection.

F. Roll cages must be squared with frame rail. No leaning or bent cages.

G. Roll cages must have a foot and leg protection bar. See Modified chassis spec. for illustration.

I. Vent post mandatory on all cars.

J. Minimum of 18-gauge steel plate required in driver’s door, extending from rear of seat to knee area.

10. BUMPERS

A. Nose cone or stock bumper mandatory on front. Rear bumpers mandatory, may be fabricated, must have rounded or capped corners.

11. SAFETY

A. Helmets are required and must be a minimum of SNELL SA2010 or SFI 31.1/2010 or newer. Manufacturer tag and SNELL/SFI sticker must not be removed. Helmet must be worn at all times when the car is on the track and must accompany the vehicle at the time of inspection. Full-face helmets mandatory with a face shield or eye protection.

B. All competitors must wear a driving suit of flame retardant nature. If the driving suit is a two-piece suit, both the top and bottom must be worn at all times.

C. It is mandatory for the exhaust system to be mounted in such a way as to direct spent gasses away from the cockpit and from area of possible fuel spillage.

D. Safety approved fuel cells are mandatory. Fuel cells must be enclosed in a metal case of 18-gauge steel and must have a protective hoop at the rear that extends at least one inch (1”) below the fuel cell. The fuel cell overflow must go to the bottom of the cell on the outside and must be fastened at the bottom of the cell, or a ball check valve must be used. All fuel cells must have a minimum of two (2) – 2” x 1/8” metal straps or equivalent metal surrounding the fuel cell. Must have safety tether on fuel cell cap.

E. Batteries must be securely mounted outside of the driver’s compartment.

F. A competition shoulder harness, at least three inches (3”) wide and a lap belt at least three inches (3”) wide are required. All belts and shoulder harness must not be no older than three years (3 years) and have dating tag. If belts are older than three years of age, you will not be allowed to race. No OEM factory type shoulder belts or straps will be allowed. Metal to metal buckles are required on the shoulder harness and lap belt. The harness must be mounted in at least five (5) points below the driver’s shoulders (sub strap). Full window nets are mandatory; no homemade window nets, with arm restraints as being optional.

G. A kill switch is required and must be in reach of the driver with the shoulder harness and lap belt fully cinched. This kill switch must be clearly marked “on” and “off”.

H. Minimum of one (1) drive shaft hoop is required and must be constructed of at least the equivalent of 1⁄4” by 2” steel and must be mounted in such a manner as to contain the drive shaft in case of breakage. The drive shaft must be painted white.

I. It is mandatory that all cars be equipped with a quick disconnect steering wheel.

J. Fire extinguisher is highly recommended within reach of driver with the shoulder harness and lap belt fully cinched.

K. All glass, mirrors and chrome must be removed from both inside the driver’s compartment and outside of car.

L. No sharp edges in driver compartment. Roll bar padding is encouraged.

M. All cars must have an aluminum racing seat with headrest securely mounted to roll cage or frame in stock position.

N. All weights must be painted white and have your car number on it. Must have a minimum of two (2) 7/16’ bolts per weight.

O. We recommend that protection be added behind driver’s seat so that spring cannot enter into cockpit.

P. Leg saver guard or drive shaft hoops required as described below:

A. Guard must mount between driveshaft and interior tin. Minimum 12-gauge steel or 3/16 thickness aluminum must run from back of the driver’s seat to the foot well and must be a minimum of 15” high. Driveshaft hoop must be a minimum of 5” from U-Joint and a maximum of 9” from U-Joint.

B. Driveshaft hoops may also be used. The first hoop must be no more than 36” from the motor plate; the second hoop must be 14” from the first hoop; and the third hoop must be 14” from the second hoop. All three hoops must be tied together with a minimum of one inch diameter tubing.

The 2020 rules are frozen for 2 years unless any unforeseen equipment becomes unavailable.

Disallowed if not allowed.

If the rules do not specifically allow a part or component, or do not allow specific alterations or modifications to a part or component, then that part component or modification is disallowed. Because of new technology, anything that is not listed in the rules must be brought to the Board for pre-approval prior to racing.

TEAR DOWN (protest) RACE CARS SUBJECT TO BEING PROTESTED

Any race car competing in the feature event, which; has a driver who executes a protest with a board member or track official prior to the start of the feature race and has tendered the required protest fee in cash.

A. Protest fee: $100.00 for the top end or $250.00 for both top and bottom end. $50.00 for the suspension or driveline. Three (3) items only.

The upper end teardown includes, but is not limited to: the removal of the carburetor, spacer plates or adapters, valve covers, intake manifold, exhaust manifold, valve train components and heads. The lower end teardown includes, but is not limited to: removal of oil pan, crankshaft, rods and pistons. Suspension and drive train includes but is not limited to three (3) items in this category: transmission, drive shaft, springs, front and rear, rear end and all suspension parts and components.

DISPOSITION OF PROTEST FEE

If, after teardown, the engine or racecar is found to be legal, 100% of the protest fee will be paid to the protested driver. If after the teardown, the engine or racecar is found to be illegal, 100% of the protest fee will be returned to the protesting driver.

PROTEST PROCEEDURE

After the feature race, a track official will notify the driver of the relevant racecar that his/her racecar has been protested. The protested driver shall then proceed directly to the designated area for inspection and teardown pursuant to the protest. Track officials and allowed representatives will then proceed, in accordance with the class protest, to tear down the engine or suspension for the protested racecar.

SPECIAL PROVISIONS RELATED TO PROTESTS

A driver may only protest one car per race. Only the Board of Directors/Officers has the final word on the legality of the racecars involved in a protest. The ABC Raceway and the Board of Directors/Officers reserve the right to inspect, teardown and enforce the Six Cylinder rules at any time prior, during or after the race program and retain the right to enforce all the rules and penalties herein written. No person shall prevent or interfere with the protest procedure.

RIGHT OF IMPOUND

The ABC Raceway reserves the right to impound any or all parts of the protested racecar.

PENALTIES AND SANCTIONS RELATED TO PROTEST

If any engine parts or suspension, drive train parts are found to be illegal whether discovered through a post race inspection or teardown, as a result of a protest or in connection with inspection by racetrack officials there shall be a fine of $200.00 and a suspension of thirty (30) days from the ABC racing season, suspension will carry over into the following season if applicable, loss of all points earned to date, and forfeiture of all money and awards earned for that event.

CONFISCATION OF ILLEGAL PARTS

The ABC Raceway and the Board of Directors/Officers will confiscate any illegal parts. Confiscated parts become the property of the ABC Raceway and may be disposed of at its discretion. Failure of a participant to surrender illegal parts for confiscation shall result in a separate penalty, in addition to any other penalties for illegal parts under these rules, of two (2) times the estimated retail value of the illegal parts (as determined by the ABC Board of Directors and its Officers).

WITHDRAWAL OF PROTEST

If a driver declares an intent to protest, and tenders the required fee, and then the driver changes his/her mind and withdraws the protest, then the driver forfeits all money and awards for the event, and shall lose all points earned to date.

REFUSAL OF PROTEST / REFUSAL OF IMPOUND

A driver, who refuses to allow an inspection or teardown pursuant to a protest, shall be subject to the penalties as follows:

First Refusal: Upon first refusal to allow an inspection/tear down pursuant to a protest, driver forfeits all cash and all contingency winnings for the event any trophies earned in the feature, plus loss of all points earned to date, plus the driver shall be fined $1,000.00 and suspended for thirty (30) days of the ABC racing season. This suspension will carry over into the following season if applicable.

Second Refusal: Upon second refusal, driver forfeits all cash and all contingency winnings for the event, any trophies earned in the event, and loss of all points earned to date. In addition, driver shall be fined $2,500.00 and suspended for one (1) calendar year from date of infraction.

PRESENCE AT TEARDOWN

Protested car’s driver or one (1) person selected by protested driver must be present. Pit crew, ABC Raceway Board of Directors/Officers, protesting car’s driver, track official and security may be present.

ALL DECISIONS REMAIN FINAL